Exhaust

Featured

I have to admit, I liked the sound of the factory exhaust. I'll also confess, though, that the FR-500 exhaust (formerly the Ford Racing M-5230-M58) is one of my favorite modifications. While the stock exhaust has a nice sound - especially for those of us that know "loud" does not equate to better performance - the 2-1/4" pipes are a bit on the restrictive side thanks to all the kinks. Nonetheless, an after-cat exhaust kit is always one of the first modifications done to open up the flow, allowing for a little more grunt.

For

background information, the FR-500 exhaust was developed by Ford Racing for use

on three highly modified 1999 Cobras,

referred to as FR-500's: "FR" for Ford Racing, and "500" for

five liters of V-8 displacement. For useless trivia, see the official FR-500

Press

Release, and two reviews from Car

& Driver or Super Ford

magazines (in addition, the FR-500

spec sheet has some more

details). These kits that were once sold through Ford Racing were actually made

at the time by Arvin-Meritor, and used 2-1/2"

T-409 stainless steel tubes (not to be

confused with T-304, or "18-8"

stainless). Adding to that, you have what are called dual-mode mufflers

in conjunction with an "X" insert between the tail pipes. For some more

background information, there is a great reference article on the kit from

the former

Muscle Mustangs & Fast Fords

magazine entitled "Dual Mode Dynamite".

For

background information, the FR-500 exhaust was developed by Ford Racing for use

on three highly modified 1999 Cobras,

referred to as FR-500's: "FR" for Ford Racing, and "500" for

five liters of V-8 displacement. For useless trivia, see the official FR-500

Press

Release, and two reviews from Car

& Driver or Super Ford

magazines (in addition, the FR-500

spec sheet has some more

details). These kits that were once sold through Ford Racing were actually made

at the time by Arvin-Meritor, and used 2-1/2"

T-409 stainless steel tubes (not to be

confused with T-304, or "18-8"

stainless). Adding to that, you have what are called dual-mode mufflers

in conjunction with an "X" insert between the tail pipes. For some more

background information, there is a great reference article on the kit from

the former

Muscle Mustangs & Fast Fords

magazine entitled "Dual Mode Dynamite".

With the FR-500 exhaust, you get plenty of torque at lower RPM's, and a noticeable increase in top-end power thanks to the aforementioned dual-mode mufflers (more on them momentarily). Also contributing to the low-end torque is the downstream "X", which also does a great job of killing any drone. It's generally been said that the FR-500, with its "exotic howl", is one of the best sounding exhaust kits that existed for New Edge Mustangs. I would agree completely with that. Unfortunately, if you want one of these kits, or any other from Ford Racing, you'll have to scour the used parts market.

Note: After all these years, the FRPP exhaust kits still get confused out there in internet land. In a nutshell, the M-58 (i.e., FR-500) exhaust is the quieter one, whereas the one known as the M-55 is just ridiculously loud. Also, they are both easy to compare visually since one has the "X" at the back (the M-58), and the other does not. Just in case this is still confusing, the official Ford Racing image of the M-5230-M55 kit should clear it up. Compare it to the image of the M-5230-M58 at the top of the page. Also, although most of the Ford Racing exhaust kits were made by Arvin-Meritor, there was an exception: the M-5230-MSC, which was actually from Borla. If you just clicked on the part number and realized it looked familiar, give yourself credit for paying attention. It actually was a copy of their Stinger system!

Now, what are these dual-mode mufflers? In the case of the M-58 exhaust, you take a chambered muffler and add a pressure-sensitive (spring-loaded) valve that opens at higher RPM to allow a straight-through flow of exhaust. Simple enough - and effective. During "normal" driving, the exhaust bypasses these valves and flows through several baffles before exiting. Once the pressure increases, the valves open and the majority of exhaust flows out essentially un-interrupted. Two paths for the exhaust to escape - hence "dual" mode. The pictures above show views of the valve, looking through the inlet on the left, and the exhaust on the right.

When I first wrote this page in 2013, my description of the mufflers was relatively basic, but as a late 2014 update, I decided it was time to dig deeper. I was fortunate to have a used set of mufflers on hand, but discovered their surface rust led to a lot of pin holes in the outer case material. The rust significantly bled through to the inner layer (they have a dual wrap of sheet steel), and basically put them on borrowed time. Since I felt they weren't going to be worth anything other than for some short-term use (so much for corrosion resistant stainless steel), I decided to cut one open to see what was really going on inside these mufflers. Although I won't get in to any theories of hot exhaust flow, I still thought it was worth posting pictures for all to see, especially if you are interested in a muffler that is a bit more on the "high-tech" side.

Ford Racing may have put some information out when this kit originally hit the market, but above are what I think are the first-ever views of what they actually look like on the inside. After some bead blasting, they cleaned up enough to clearly show not only the valves, but the baffles. In the image on the left, the inlet is at the bottom, with a nice line of sight through the valve and straight out the back. The right image is looking toward the exhaust, and has an even better view of the valve. Each picture also gives a clear view of the larger central chamber.

Once I had the cans open and had the chance to look at them, I wished I knew specifically what went in to the design of each baffle for the purposes of flow and noise cancellation. The pictures below also give better views across, with the inlet on the lower left of the left image (opposite on the right). Since the inlet is actually perforated (noticeable in the picture above), it would allow some of the exhaust to flow in to the front chamber, while most passes in to the second chamber. The gas then flows across the case, through the opening opposite the valve, in to the "main" chamber, across again, then out the back (all this if the valve is closed). The smaller third chamber, and larger rear chamber have openings in them that don't allow the exhaust to flow out, but are most likely there to control the sound.

Interestingly enough, the dual-mode muffler can still be found on Corvettes and plenty of exotic cars, but nothing from Ford for the Mustang (although that is actually going to change with the new GT-350). There are, however, aftermarket versions that do actually have valves in them - offering another path for the exhaust - except they are marketed more as a method to control sound. One is vacuum controlled, made by a company named Waldron, which calls it the "Driver Controlled Exhaust" (check out their patent application for more information). The other, using a manually adjusted valve, is the Vari-Tune made by BBK Performance. Both appear to be available in an offset configuration that would be adaptable to most cars, but neither would work on the IRS exhaust thanks to its unique in-line arrangement.

Since I feel lucky to have the FR-500 exhaust in my possession, I will add that if this wasn't the case, my second choice would have been the now-discontinued Borla "Touring" kit, or the other version they made for Steeda. Sometimes a nice rumble is the way to go - definitely not obnoxious - which makes these perfect. Even better, the Steeda version was nicely priced at right around $600, and with the exception of their logo on the mufflers and tips (which have a 3-1/2" diameter compared to 4" in the other kit) it is identical. Not only is it another unique exhaust, it really sounded nice.

In any case, it's very unfortunate that the FR-500 exhaust has become extinct since the market for them (and the other FRPP kits) would probably be bigger today than it may have been several years ago. The mufflers were even also sold at one time through Ford Racing under part number M-5230-BP2, but like the exhaust kits, they are no more. I'm fortunate to have this kit on my own car, and as you can guess, I absolutely love it! Two obligatory pictures of the exhaust, accompanied still by the factory mid-pipe, are shown below. Not only does it work, it just looks fantastic.

Note: The Arvin-Meritor sourced factory tail-pipes were the same for each year of the New Edge IRS Cobra. The exception is that they were revised after it was discovered that the initial 5,300 vehicles from the 1999 model year were down on power, a debacle that led to cancellation of the 2000 program. Each side, however, has a part number that in Ford parts-speak is actually from 2000 due to the update (also original-equipment beginning with the 2001 models), and were service replacements for all years including the Terminator. Although they are long obsolete, the driver's side was YR3Z-5230-CLH, and the passenger side was YR3Z-5230-CRH.

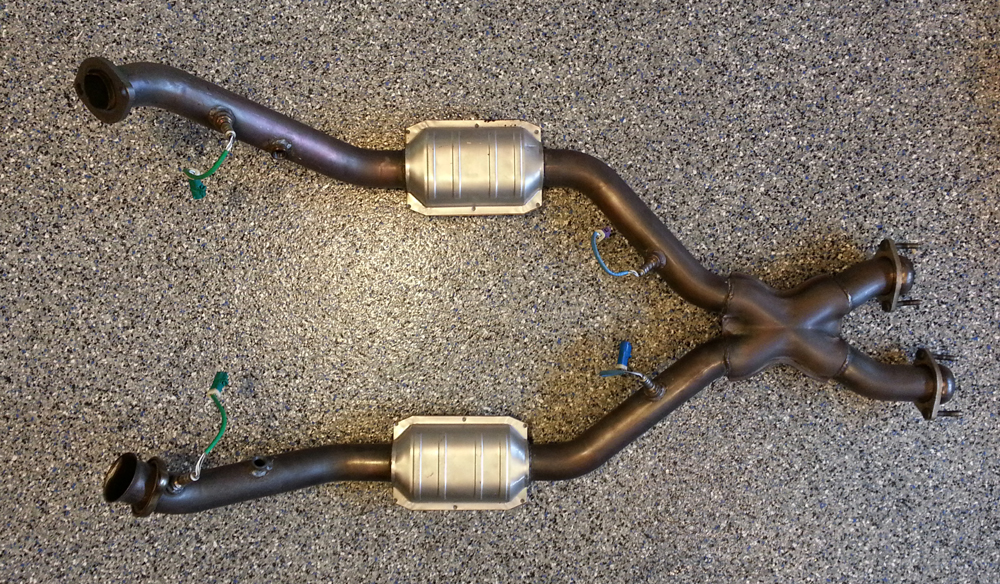

The Terminator actually had

two different "H-pipes" from the factory for both model years. The first version

was a bit more on the "compact" side and had four catalysts that were roughly all

the same size (technically, it was

two "pre-catalysts" followed by two catalysts). It carried the part number

2R3Z-5F250-EA.

The second version, introduced in 2004, was changed with regards to the rear catalysts, which were now

almost double the original size, and became

3R3Z-5F250-GB.

The Terminator actually had

two different "H-pipes" from the factory for both model years. The first version

was a bit more on the "compact" side and had four catalysts that were roughly all

the same size (technically, it was

two "pre-catalysts" followed by two catalysts). It carried the part number

2R3Z-5F250-EA.

The second version, introduced in 2004, was changed with regards to the rear catalysts, which were now

almost double the original size, and became

3R3Z-5F250-GB.

The significance of the revision was that the two rear oxygen sensors - of four total - were forward of the catalysts in '04 and would require extensions when switching to an aftermarket mid-pipe (which placed them much farther back, on par with the factory 2003 locations). More importantly, the larger, higher-flowing catalysts used in 2004 were also, to the best of my knowledge, part of what led to its 1MPG gas mileage increase. This was followed by the removal of the $1,000 "gas-guzzler" tax that 2003 owners were hit with - what a break!

Note: The oxygen sensors are color coded, which is somewhat discernable in the picture of my mid-pipe below, but Ford recently updated the part numbers so that one works in all positions. The front two had been green and carry the Ford part number 5C5Z-9F472-AA. For the rear, the driver's side was 5W6Z-9G444-AA and has a blue connector. The passenger side, with the purple connector, was GU2Z-9G444-A. This had been due to the difference in the transmission harness which were unique for both years (see my Drivetrain page). According to the guys at Tasca Ford, the "GU2Z" part number is now universal for all positions. It seemed strange to me since I knew the plugs had been different, but apparently Ford made it work out with the single part number.

Originally, I was pretty content with the factory mid-pipe, and had I not scored a like-new 2-1/2" Magnaflow "X-pipe" for less than half of its retail cost, I may not have bothered with the swap. In any case, I discovered this one (also T-409 stainless steel like the Ford part) is not only a work of art, it has an OEM fit. Although there are plenty of options out there to suit individual tastes, I was perfectly happy having at least two catalytic converters in place to keep my conscience from getting the best of me.

Another bonus with an aftermarket mid-pipe is the flexibility to place wideband oxygen sensors in locations that are easily accessible (see the kit I used on my Electrical page). The first bung had been welded in adjacent to the clutch fork cover, and a second was then added on the opposite side for protection of both banks (only the one picture is shown above right, but you get the idea). This is still possible with the OE mid-pipe, but definitely a bit more of a squeeze. If you are using an "off-road" pipe and have a custom tune, this is even easier since the extra sensors can just be swapped for the two in the back (assuming they are now turned off). With a mid-pipe like this, it is simple enough, and works great!

Overall, Magnaflow did a great job of developing an exhaust component that fits perfectly and flows better than stock. I don't have any comparison of before & after power numbers, but the consensus is that the aftermarket mid-pipes are generally good for 8-10 HP. I can't say I noticed a big increase in power from the swap, but the sound level did pick up a bit with two less catalysts in the system. So far, I have been OK with that, especially since the noise isn't anywhere near being excessive.

Note: When it comes to welding on additional bungs for wideband sensors, one minor annoyance is the potential presence of "slag" afterwards. Not to worry though, a simple spark plug tap, like the Lisle 20200, will allow you to chase the threads to clear out any crud before you install the new sensor. One end of it is the exact M18-1.5 found on the O2 sensors, and for less than $10, it's a great tool to have handy.

Anyone that has spent time under the hood of a Terminator, especially with the Eaton supercharger, will agree that there is some serious heat radiating out of this engine. There is no doubt that when it comes to those high temperatures, the OEM cast iron exhaust manifolds are also one of the culprits. I decided to do something about it, but I had no desire to mess with long-tube headers, nor did I want to deal with leak-prone aftermarket "shorties". The next best thing in my opinion: stock manifolds with a ceramic coating courtesy of Jet-Hot.

I was lucky when I started this since I found a new set of take-off manifolds that were pulled from a crate engine which were the perfect donors, especially since they were completely free of rust and soot. The finish now is amazing - done in the Extreme 1300 Satin, and coated on the outside as well as the inside. They not only look great, but have definitely helped with the heat (plus, the stock manifolds actually flow pretty well). With better air flow around the engine thanks to the vented hood, I've definitely taken a load off some of the accessories. This is especially important with the alternator, which tends to succumb to the high temperatures due to its location low on the front of the engine.

Since my Cobra has low-miles and doesn't see rain or snow, all the fasteners came out without any hassle. Just to be on the safe side, however, I did go ahead and buy all new Ford studs and locking nuts, so that made the assembly a bit easier. I also made sure to get new OEM gaskets which are really the way to go - they just don't leak! Not surprisingly, they originated with the Lincoln Aviator (see my Castings page), and if you need to score a set, their part numbers are 2C5Z-9448-AA and 2C5Z-9448-BA. They are also side specific since the oil dipstick is in the way, necessitating a two-piece set on the left head. The pictures below are actually an update from late 2015: the manifolds were transferred over to the Aluminator, and after almost two years, they still look great.

The downside to a project like this is the installation: getting at the exhaust manifolds (or headers) on the DOHC engine is a nightmare. If you are completely masochistic, try tackling this by attempting to fit your hands and tools behind the factory K-member. Just be sure to leave yourself a whole lot of time, and prepare the people around you for all the expletives that will be coming out of your garage. The "easiest" way to accomplish this swap is by dropping the K-member, if you happen to still have the stock part. It's tedious, but it is the only logical way to get at everything. Since I happened to have a Steeda K-member (documented on my Chassis & Steering page), it worked out perfectly since there is now a ton of room to work.

Note: It is also worth replacing the "donut" gasket that fits between the mid-pipe flange and exhaust manifold on the passenger side. Take note, however, that it has a thicker flange on one side that gives it a specific fit. I've changed this a few times now, but on a previous occasion, failed to notice the orientation when I slipped it back in - oops. For the best seal, that thick flange should face towards the exhaust manifold, otherwise you could end up with a very slight "tick" - the last thing any Terminator owner wants to hear. The gasket is inexpensive and available from Ford as XR3Z-9450-AA, or through FelPro as 61203.