Castings

Cylinder head background

The "new" Terminator

four-valve Dual Overhead Cam (DOHC) heads were

actually derived from the

Lincoln Aviator

platform, which began with the 2003 model and ran through 2005. Although Cobra-specific heads were considered early in the program,

they were "...abandoned due to cost and complexity" (quote from a friend at Ford),

as well as in the interest of production lead time. In addition to use on

the Aviator and Terminator, these heads also went in to service on the DOHC engines of the Mercury Marauder and

Mach 1 Mustang

(both in 2003 and 2004).

The "new" Terminator

four-valve Dual Overhead Cam (DOHC) heads were

actually derived from the

Lincoln Aviator

platform, which began with the 2003 model and ran through 2005. Although Cobra-specific heads were considered early in the program,

they were "...abandoned due to cost and complexity" (quote from a friend at Ford),

as well as in the interest of production lead time. In addition to use on

the Aviator and Terminator, these heads also went in to service on the DOHC engines of the Mercury Marauder and

Mach 1 Mustang

(both in 2003 and 2004).

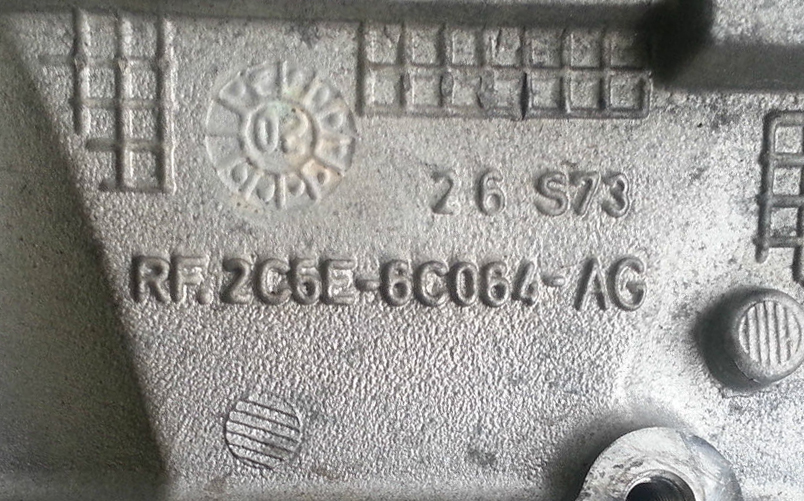

A lot of confusion and debate has existed over the years as to which heads are "better", or "updated". There have been five production versions of the 2003-up 4.6L DOHC Tumble-Port (single intake runner) "C" head, with a final revision appearing in 2005. They can all be identified by their engineering, or casting number (not the same as the part number), which is embossed above the exhaust ports on the right side of each head. Although their actual casting number would be something like 2C5E-6C064-DA, I'll generally refer to them solely by their suffix of two letters (i.e., "DA") for the sake of simplicity. All the heads in this program do also have casting numbers beginning with "2C5E", so be aware of that if you are on the hunt for any of them.

The "tick" & the "stripe"

The biggest issue with these heads has been coolant flow, or lack thereof, at the back of the driver's side. While the passenger side allows for the coolant to exit at the front and back of the head (the back for flow to the heater core), the driver's side coolant has only one path out: the front. This allegedly caused problems around cylinders 7 & 8 due to elevated temperatures, with those valve seats tending to slip loose, especially on the exhaust side. From here, the infamous "tick" occasionally developed (although I'd call it more of a rattle). The first Tech Bulletin addressing this was TSB 03-11-04, which pertained to the earlier models built prior to November 1st, 2002. Before this point, the castings on both cylinder banks had been the same, but now there was a new head for the left bank. Although it became unique for that side, there were still more versions to come.

It is definitely worth mentioning that some engines were delivered with blue paint, or a "stripe" on their heads. Not only could it be seen on the driver's side head, but sometimes the passenger side, or both sides at once. The myth is that you have an updated head, or heads, if you see it. The ONLY way you will know which heads you have is by looking at the casting numbers. The blue paint has to do with the build and assembly process, so if you see it on your car, don't get all excited. Yes, you could technically have a head that is newer, but if you see the blue paint after all these years and assume you have the latest versions, you would be better served by digging deeper.

Interestingly enough, the Terminator at least has the flow path of coolant on the right side, so that is an advantage. It is even in contrast to the Aviator and Marauder, which only allowed for coolant flow out the front of both sides (then again, they weren't carrying around a supercharger). Fortunately, there were people out there that were creative enough to come up with kits that allowed for an escape of the coolant from the back of the driver's side head to alleviate the potential for "hot spots". For details on them, see my Cooling page.

Note: Another potential "problem" with these heads was related to the spark plug threads: most had just four threads per plug. The torque for the spark plugs is a mere 11 ft/lb, and chances are, this value gets exceeded on a regular basis which damages the threads. Once that happens, your only options were replacement, or repair with a kit by Lock-n-Stitch (approved by Ford per TSB 07-21-2) or Timesert.

Early heads

The

first Terminators had AF, then AG

castings. These versions were used on both banks, and had the squared exhaust

ports that continued through the final revision (compared to the oval ports on

the '99/'01 Cobra). When the unique driver's-side-only

head was put in service late in 2002, it was the DA casting. This is also the replacement specified in the TSB

mentioned above that referenced the first "tick" issues. The image

below and to the right shows a DA head with the blue paint, and for

contrast, click the thumbnail to see another DA without paint. Note the date stamps of "02" on the

AF & AG heads, with both "02" and "03" on the DA

versions.

Although the picture of the AF head below and left could be better, it also has the blue paint. That particular engine I came across happened to have been built on 5/1/02 - probably one of the first runs of engines for Job #1 production that began on 5/28 of that year. Additionally, it was another engine where the paint was on both heads, which can be seen more clearly from the back of the engine. All of these also had the four-thread spark plug holes.

Expanding on the DA heads, a small number of late '03 builds (including some Anniversary models) did have them on both banks, but there is a catch: the interchangeability between sides has to do with oil supply passages. This pertains mainly to the primary chain tensioners with their necessary oil passage on each head, which required modification from the original supplier to use on the opposite side. That supply feed was blocked off with a plug on the back of the head when it was not needed in the earlier castings, but it and other plugs could be opened if used on the other bank. Additionally, there is a restrictor under each front cam cap that must be in the appropriate position depending on where the head sits. With the last revisions, the mounting pads on the rear had no oil passage, which was what made them side specific.

Note: For some additional trivia, there were actually "pre-AF" heads that came along before the Aviator program. These versions also stemmed from Lincoln (the FWD Continental, with its Intech V8), and had oval exhaust ports. They were AA, AB, AC, and AD, also with the 2C5E prefix (there might be AE's out there as well, but I've never acquired pictures). These heads were in service from '98 through '02 - before the demise of the Continental - leading to the newer versions arriving "just in time" for use in the 2003 model year.

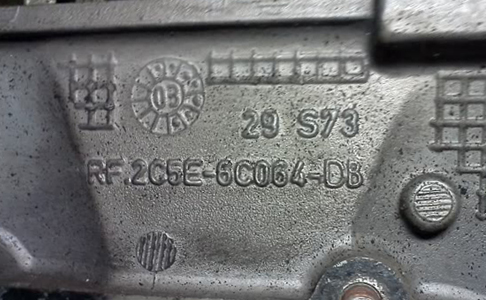

Final revisions

The last two castings were updated with nine threads for the spark plugs and were generally accepted to provide better coolant flow. Although the casting numbers on each head are the same, they are not interchangeable and are built specific for each side (due to the lack of the additional oil ports). The first version, as seen below and to the left is the DB that came on the 2004 models, including the Mach 1 and Aviator. This head also was also used on some of the last '03's that rolled off the assembly line in June and July of 2003 (note the '03 casting date). If you happen to have a Terminator that was built at that time - especially if it was a 10th Anniversary edition - you may be lucky and have the '04 heads already.

For the 2005 model year, with some heads cast in late 2004, the last revision was released: the DC, which was found on the Lincoln Aviator. This head was also referenced in TSB 06-05-13 under the Ford part numbers 2C5Z-6049-BAB and 2C5Z-6049-CAB (which, again, differ from casting numbers), and if you wanted it for the other DOHC engines, it was a retrofit only. Additionally, it was the same head sold by Ford Racing as M-6049-464V and M-6050-464V. Unfortunately, these heads are no longer sold through Ford Racing, and as of mid-2015, they were being phased out by Ford. Although some may be available for purchase directly from Ford - with a core charge, of course - it's another item for the 4.6L engine that is becoming extinct.

Another version of the DC head that was around for a very brief period was the ported set available only through Ford Racing. These were modified through Roush at the time, and delivered an increase in flow over the OEM castings. The original part numbers for them were M-6049-464P and M-6050-464P, and other than the port work, they were identical to the last casting. If you got your hands on a set of these, feel fortunate since they were a bargain back then and were incredibly well done.

Note: I've never been able to get a straight answer regarding the round date stamps, but you may notice the digits are surrounded by twelve small blocks. It would seem intuitive that they would correspond to the months in each year by simply counting the dots that are placed there. Above and to the left, there are seven dots surrounding the "03", so that head was probably cast in July. To its right, the "08" has just two dots - most likely meaning it was produced in February of that year.

Camshafts

It's probably worth mentioning the camshafts briefly since, after all, they are an important component. The cams, like the heads, were not unique to the Terminator, but were also brought over from Lincoln. For the exhaust, they originated out of the 2000-2002 FWD Continental program, and were from the 2003-2004 5.4L Navigator on the intake side. In addition to use on the Terminator (and vehicles that use the same heads), they were also even carried over to the Shelby GT-500's from 2007-2012.

As far as the specifications are concerned, Ford states lift on all is 10mm (0.3937") at the valve and 5.54mm (0.218") on the lobes. Duration @ 0.050" is right around 185° for the intake and 195° on the exhaust side, but those numbers sometimes vary by a degree here and there. As for lobe centerline, 114° seems to be commonly agreed upon. In addition, the cams raise intake valves with a 37mm diameter, and exhaust valves that are 30mm. The engineering numbers on them have varied slightly over the years, but the chart below also has the final part numbers for general reference.

|

Position |

Engineering number | Part number |

| Left Intake: | YL7E-6A271-AB | YL7Z-6250-BA |

| Left Exhaust: | YF3E-6A273-AB | YF3Z-6250-DA |

| Right Intake: | YL7E-6A270-AB | YL7Z-6250-AA |

| Right Exhaust: | YF3E-6A272-AB | YF3Z-6250-AA |

Note: When it comes to "factory" camshafts, a great bang-for-the-buck when building a new engine, or improving a current one, is a set from the '96 - '98 DOHC Cobra. The intake camshafts offer some additional breathing with 20° more duration over the Lincoln versions in the Terminator, which is perfect for forced induction (the exhaust side is essentially the same). Additionally, these use 12mm mounting bolts, increasing the high-strength options out there to secure them. While they are not always easy to find, they do work real well, so it helps to have the engineering & part numbers handy in case you are on the hunt!

Engine blocks

In the realm of engine blocks, there are always going to be differing opinions on they way to go: stay with the factory iron, or swap to lighter weight aluminum. If you are a road racer and looking to achieve the optimum balance, the extra 60-80 pound weight savings with aluminum is definitely worthwhile. The choices here aren't as extensive as the heads, but there is still some confusion out there.

For

the most part, the factory iron block is just a standard 4.6 SOHC Romeo block

with some minor modifications suited to the Terminator. The original block once

carried Ford p/n 3W7Z-6010-AB, but like so many other items, has been updated in

recent years. The new block is listed now as 7L2Z-6010-B and is still available

through Ford. The thumbnail shows the casting number from one of the original

blocks, but I don't honestly know if the new part number is based on this

casting or a revision. The iron block also could be purchased through Ford

Racing up until recently, under their part number

M-6010-D46, although they listed it solely

as a 2V block.

For

the most part, the factory iron block is just a standard 4.6 SOHC Romeo block

with some minor modifications suited to the Terminator. The original block once

carried Ford p/n 3W7Z-6010-AB, but like so many other items, has been updated in

recent years. The new block is listed now as 7L2Z-6010-B and is still available

through Ford. The thumbnail shows the casting number from one of the original

blocks, but I don't honestly know if the new part number is based on this

casting or a revision. The iron block also could be purchased through Ford

Racing up until recently, under their part number

M-6010-D46, although they listed it solely

as a 2V block.

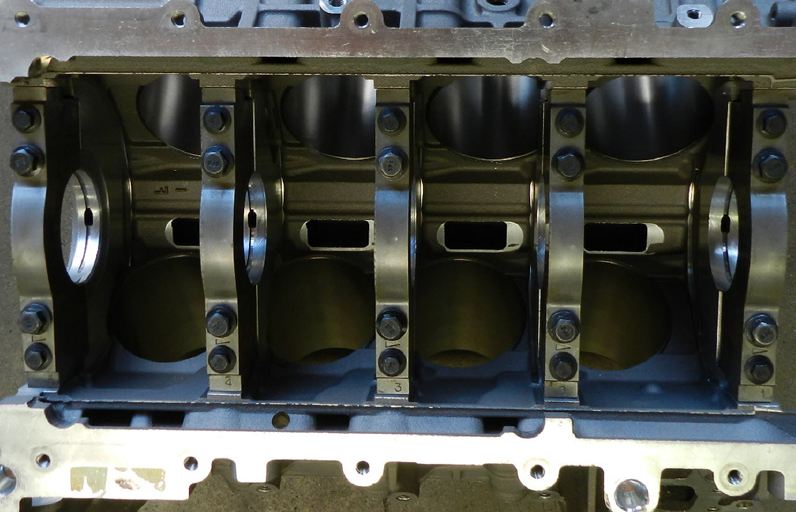

Going back to 1996, the DOHC 4.6 Mustang engines were built using the Italian-cast Teksid aluminum block that was derived from the '93- '98 Lincoln Mk-VIII program. This block stayed in service until 1999 when Ford eliminated the main cap jack-screws, which gave it a new casting number (seen above the oil pan rail on the left side of the block). Below are two pictures of those casting numbers, the left being the '96-'98 "F6LE" block - with a jack-screw visible - and the right showing the '99 "XR3E" block. The Teksid blocks are also easily identified by the squared pattern in the intake valley.

Note: The first Mk-VIII blocks were "F2LE..." castings, which date to the early-90's. They are perfectly viable for use, and are also identifiable by their unique "oval dish" in the intake valley. Additionally, there were FWD Continental Teksid blocks that had "F50E..." or even "F60E..." casting numbers, but are unusable in RWD applications.

In 2001, Ford made another switch to the aluminum blocks and began producing them at the Windsor engine plant, hence them being referred to as the "WAP" block, for Windsor Assembly Plant. These blocks are easily identified by the "W" stamp above the casting number (which is on the right side now), as seen in the picture below, and to the left. In contrast to the "waffle" pattern in the valley of the Teksid blocks, the WAP had a diamond pattern. This block was also used in, among other applications, the 2003 & 2004 Mustang Mach 1 and Lincoln Aviator, carrying Ford part number 3L2Z-6010-AA (casting number beginning with "1L2E"). Even with the switch in 2001, some Cobra owners have reported finding a Teksid block in their car - most likely due to a purge of current stock - a nice score!

The latest offering in aluminum was the Ford Racing Aluminator which used, believe it or not, the block from the 2005-2010 3-valve Mustang GT. This block was coincidentally also cast in Windsor, Ontario, but this time by a company called Nemak. This new block can be distinguished by its revised casting number (beginning with "3L2E") as well as the Nemak logo, shown above, and to the right. It also has the diamond pattern in the intake valley, but don't let that confuse you - it's not just a "WAP". According to the Ford Racing official blurb, this is one stout block that will rival any previous offering in aluminum (with my emphasis added):

"The foundation of these engines is the 4.6L engine block used in the '05-to-present Mustang GT. Thanks to a technology partnership with Cosworth, this new block features strength unmatched by any previous production 4.6L aluminum block. The employment of zircon sand for the casting molds, a chilled bulkhead cooling process, as well as a proprietary method of pouring the aluminum results in a denser block with better alignment in the aluminum's grain.

The casting also features increased main web thickness and round main cap windows to alleviate stress cracks often found with rectangular windows. The main caps are standard six-bolt but are now ball-burnished for greater strength. In production testing, the new block more than doubled the duty cycles of other aluminum 4.6L blocks."

At one point, this block could be purchased through Ford Racing in several different configurations, or bare as M-6010-A46SC, but they have been discontinued. Not to worry though, you can still buy it directly from Ford, p/n 8R3Z-6010-A - at a retail price of around $2500.00. Along with use by FRPP, the new block also became the service replacement for all years of 4.6 aluminum blocks prior to 2005.

Note: The Nemak logo also appears in a place other than on an engine block. If you happen to own a Ford GT or a Shelby GT-500, you may have noticed the unique stamp on the cylinder heads that are shared by both 5.4L engines. In addition, the former Ford Racing FR500C head (p/n M-6049-DAC) was an earlier version of the same casting.

While the final revision is identified with the "CC" casting suffix, there were also two earlier versions that found their way in to some 4.6 SOHC trucks in 2003 and 2004 (I believe this was due to glitches at the Romeo plant, necessitating use of the aluminum block in order to avoid interruption in production). Those blocks are identified with casting numbers that end in CA or CB and are probably every bit as good as the CC. Just an FYI! If you happen to own a 2005 Aviator, or find an engine from one, you could luck out twice in that you would have not only the new heads, but most likely, the latest block.

For some more trivia, another set of numbers that appears on them - this time at the front, adjacent to the water pump bore - is known as the "Pin stamp". During assembly, the piston selection is based on the finished bore diameter, which is shown in a sequence of digits (eight of them for eight cylinders in this case). The bores are given a single digit 1 - 3, which is indicated in order to let the assembler know which grade of piston to select. Each piston (with rod), would be marked accordingly, which sometimes was as simple as a paint dot in red, blue, or yellow. Pretty cool.

One last item when it comes to 4.6L engine blocks are the main caps. All the aluminum blocks have six-bolt caps whereas the iron has four - that's also including the jack-screws on the sides. I've occasionally heard comments about how stout the iron block is - thanks to its "six-bolt mains" - but that would be the Windsor iron block, not the Romeo version used in the Terminator. Just for reference, all are shown above. Clockwise from the upper left: Teksid, WAP, Romeo iron, and Aluminator.

After all this, you are probably wondering: How much do these blocks weigh?!?! Not to worry, here's a small chart that sums it up. Check out which one of the aluminum blocks is the beefiest...

| 4.6 Block | Weight (lbs) |

| WAP | 80 |

| Teksid | 85 |

| Aluminator | 90 |

| Romeo iron | 155 |

What you chose to do with this information is up to you. It's obvious that as far as cylinder heads go, the last castings are going to be the most sought after, but there are plenty of Terminators still using some of the earlier versions without issue. As for the blocks, that debate will probably never end. The standard for an "upgrade" has been the Teksid, but that may not be the case any longer. The "popular" opinions out there probably always will be that a WAP block is not sufficient for any forced induction car, but like the earlier heads, there are most likely many of them being used successfully. I'm fortunate to have a block (and new ported "DC" heads) as part of my Aluminator project, but there was no doubting the strength and durability of cast iron all along!

Note: With regards to the comment up above about the Windsor "six-bolt mains", it is worth making a clarification there. The outer "bolts" are actually just locating dowels, but at a glance, the appearance of having six bolts is still there (similar to the aluminum blocks above). I'll give thanks to Anthony in West Palm Beach, FL for bringing that to my attention. It was not a detail I looked at in depth, but I was glad to acquire the additional information. In any case, it is why I enjoy getting comments and feedback from those that find this site useful and are glad to contribute more to it. Many thanks, Anthony!