Drivetrain

Featured

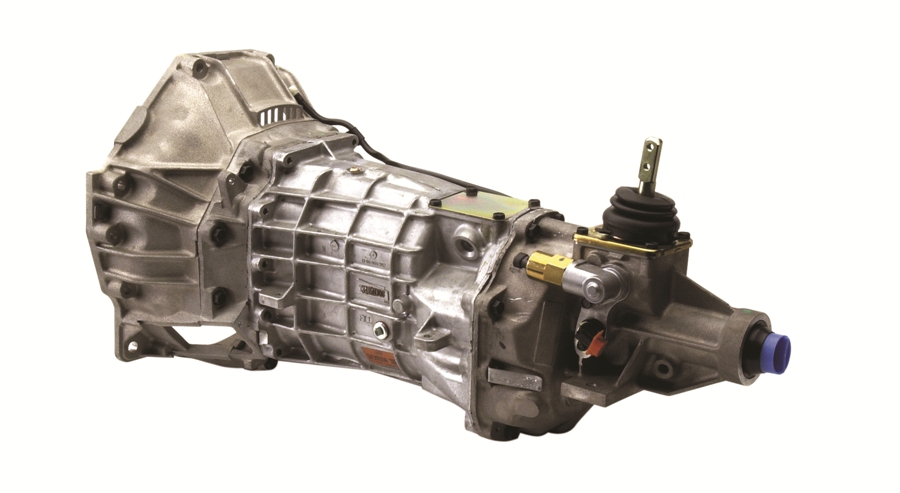

The T-56 got its start in the early 90's with the Dodge Viper and GM F-Body line. It evolved from the 5-speed T-5 as an alternative to handle higher power engines, this time as a double-overdrive 6-speed. Back then, it was manufactured by Borg-Warner, which ultimately sold off the transmission division to Tremec. In previous years, the T-56 gained popularity by finding its way to other vehicles such as the Corvette, Aston Martin Vanquish, and the Cadillac CTS-V just to name a few.

Tremec has since improved on the base model with an aftermarket Magnum version along with its OE 6-speed twin TR-6060. As for the Terminator, the one developed for use behind the supercharged engine has generally done well, but if a Magnum is on your wish-list, an informative article from the Tremec Blog will provide some nice details. They are also available through Ford Racing in a "Close-Ratio" version as the M-7300-M6266 (2.66 first gear), or the "Wide-Ratio" M-7300-M6295 (2.97 first gear).

Back to the T-56, the chart below lists the Tremec part numbers along with the accompanying information from Ford and a breakdown of the gear ratios. For whatever reason, the part numbers were changed from 2003 to 2004, but I've never been able to ascertain the differences other than being told they are "Basically the same..." by a rep at Tremec. All models of the transmission have 10-spline inputs shafts, with output shafts in 27 splines for the Terminator, and 31 splines for the Ford Racing & Cobra R versions. If you happen to get your hands on one of the latter units, a matching driveshaft yoke (not "yolk" - that's part of an egg) is available from FRPP as M-4841-A.

|

Model |

Tremec P/N | 1st | 2nd | 3rd | 4th | 5th | 6th | R |

| 2003 Cobra: 2R3V-7003-AB | TUET1694 | 2.66 | 1.78 | 1.30 | 1.00 | 0.79 | 0.63 | 2.90 |

|---|---|---|---|---|---|---|---|---|

| 2004 Cobra: 4R3V-7003-AA | TUET2060 | 2.66 | 1.78 | 1.30 | 1.00 | 0.79 | 0.63 | 2.90 |

| Ford Racing: M-7003-F | TUET1260 | 2.97 | 2.07 | 1.43 | 1.00 | 0.80 | 0.62 | 3.28 |

| 2000 Cobra R: YR3V-7003-AA | TNET9249 | 2.97 | 2.07 | 1.43 | 1.00 | 0.80 | 0.62 | 3.28 |

Note: While the differences in the transmission from '03 to '04 may not be obvious, it is important to mention that they do each have their own specific wiring harnesses which are not directly interchangeable. For 2003, the part number of the harness was 2R3Z-15525-DA, and for 2004, it is 4R3Z-15525-FA (the latter may still available, while the former is long gone - no surprise). While they look similar, the position of the rear oxygen sensor plugs - which are part of this harness - dictate the need for a unique version for each year. I suppose it is also possible to use the '04 harness on an '03 if you add O2 sensor extenders, but I have not researched it thoroughly. In any case, the extenders are easy to come by and are inexpensive if you want to try.

One area generally agreed upon for "improvement", especially when power levels are greatly increased, is the aforementioned input shaft. From the factory, the 1-1/6" diameter shaft is standard (again, with 10 splines), but it has been known to twist, or even break from hard drag-race launches - if that is your thing. The standard upgrade here is a 26-spline, 1-1/8" piece that is more resistant to damage due to not only the increased spline count, but the larger diameter. The 26-spline shaft is also standard on the Magnum.

Some will also say the T-56 is a bit "notchy", but that can be considered a matter of personal preference. Interestingly enough, it uses Mercon-V Automatic Transmission Fluid (ATF), which is an update from the original Mercon-III that is referenced on a label adhered to the transmission (and mentioned in the SVT Supplement). My choice, based on personal experience (as well as another conversation with a tech at Tremec) is Mobil1 ATF. Mine shifts fine with the synthetic ATF, but like so many other things, there will be plenty of different opinions here as to what is "best".

About the ATF, it has roughly the same viscosity as a 20-weight crankcase oil (per the SAE J300 classification), which is perfect for the fluid to flow through all the small internal passages. Many, however, have switched to a heavier "Synchromesh", or "Manual Transmission" fluid with good results. Again, personal preference. By the way, the T-56 takes 3.9 liters of fluid, which easily rounds off to 4 quarts!

![]() If you have ever worked, or are planning to

work on a T-56, help yourself to the service manual by clicking

the thumbnail. If you've never dug in to a manual transmission and aren't even

quite sure what is going on inside, there is an

animation on

YouTube that lays it out quite nicely. Also, there is plenty of other information

on the internet, including links to some of the special tools that are needed to

remove some of the gears, found through any number of search engines.

If you have ever worked, or are planning to

work on a T-56, help yourself to the service manual by clicking

the thumbnail. If you've never dug in to a manual transmission and aren't even

quite sure what is going on inside, there is an

animation on

YouTube that lays it out quite nicely. Also, there is plenty of other information

on the internet, including links to some of the special tools that are needed to

remove some of the gears, found through any number of search engines.

Note: If you've ever dropped your T-56 or intend to at some point, definitely take care when it comes to its unique mounting bracket - they are obsolete and real tough to come by. At one point the Ford Racing part (M-5059-B) was readily available, as was the same replacement under the Ford part number, but those days are long gone. As of now, the only option available from the aftermarket comes from Stifflers, of Mooresville, IN: their TCB-M20. It's actually a real nice upgrade with its polyurethane bushings, and even has a matching driveshaft safety loop for the drag racers (along with plenty of other cool suspension components). If you are lucky enough to find a nice used one, definitely grab it, otherwise it's not the end of the world if your original part has seen its better days and is ready for the scrap bin.

One of the weak links in the drivetrain

has always been self-adjusting, plastic clutch quadrant

that comes from the factory. Mustang owners going way back have generally

replaced it with a quality aftermarket kit that is not only stronger (usually

aluminum), but manually adjustable. Along with that, you have a choice

of using a cable with a threaded end at the clutch fork, or to make it real

easy, an adjuster at the firewall.

One of the weak links in the drivetrain

has always been self-adjusting, plastic clutch quadrant

that comes from the factory. Mustang owners going way back have generally

replaced it with a quality aftermarket kit that is not only stronger (usually

aluminum), but manually adjustable. Along with that, you have a choice

of using a cable with a threaded end at the clutch fork, or to make it real

easy, an adjuster at the firewall.

I originally went with a package deal through the former Fiore Performance (see thumbnail), although I am not sure if this particular kit is available any longer. The nice feature is the "micro-click" firewall adjuster that locks itself in to position without any need for a jam nut. It is definitely easy to tweak from under the hood, and had functioned perfectly up until I installed my new Centerforce clutch (see next section). For whatever reason, with the new clutch, I needed to take up just a bit more of the cable which meant the firewall adjuster would hit the cam cover (the MM kit also includes a spacer to fix this). Not to worry though, I picked up a new quadrant through Ford Racing (M-7583-A) that allowed the cable end to pull forward a bit more due to its revised outline.

Installation of these are relatively straightforward, but for a nice set of instructions that will apply to just about all of the kits, look no further than Maximum Motorsports for details on both the clutch quadrant as well as the firewall adjuster. One item worth mentioning is the alignment of the cable in the adjuster: you have to cut off the factory mounting bushing at the firewall end and replace it with a piece of 3/4" heater hose to center it in the new adjuster. The Fiore adjuster originally came with a thin piece of clear tubing for this, but it was nowhere thick enough to hold the cable straight, so I tossed it and added the short piece of heater hose (this is clearly illustrated in the MM instructions).

Also, be sure to set the tension so the throwout bearing rides lightly on the clutch diaphragm fingers, NOT floating above it! Some geniuses on various forums will tell you that a spring placed on the clutch fork under the cable end is necessary to keep the bearing lifted off the fingers, which is absolutely not the case (it does not do this from the factory). For more on it, another page on the MM site appropriately titled How to Adjust a Mustang Clutch Cable is a perfect read on the subject.

Like so many other aftermarket parts for the Mustang, there are plenty of vendors that make these kits, so it is very easy to source one that fits your needs or budget. As usual, opinions on which one is best will be all over the map. If you do desire trouble-free clutch engagement, don't hesitate to pull the weak plastic out from under the dash and make the upgrade.

Note: The best cable out there has been the OEM Ford version (p/n 2R3Z-7535-AA), but they have gone obsolete in recent years. Even the "universal" versions from Maximum Motorsports, based on the Ford cable, are now out of production. Unfortunately, all the other generic cables out there are most likely junk and just won't last. While I have no firsthand knowledge of the adjustable versions sold by Ford Performance, I imagine they are OE quality, so they could be an option in a pinch. If you planned ahead and grabbed a spare Ford cable, consider yourself lucky.

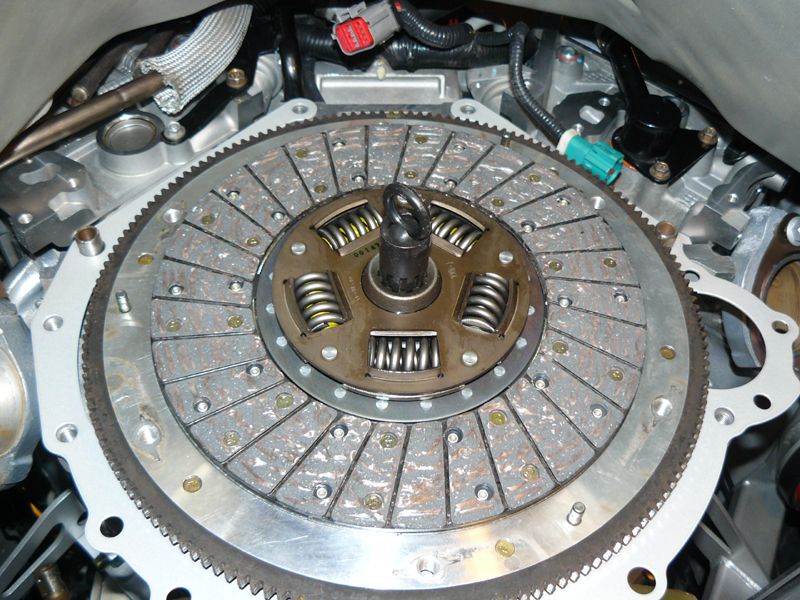

The

factory clutch is

pretty stout, but the extra pedal effort had never really bothered me. I've

heard plenty of complaints over the years about how

"stiff" it is, but in

my opinion, that is the price you pay for a performance-oriented, cable-actuated clutch. Unfortunately (or fortunately, depending

on your point of view), the factory 11"

Valeo clutch, that once was easily obtained through Ford Racing (M-7560-D46),

has been discontinued, so aftermarket replacements have become the norm. If you

really want to obtain a Valeo clutch as a replacement, their part number for the

'03/'04 Cobra kit

is (or was) 52802032.

The

factory clutch is

pretty stout, but the extra pedal effort had never really bothered me. I've

heard plenty of complaints over the years about how

"stiff" it is, but in

my opinion, that is the price you pay for a performance-oriented, cable-actuated clutch. Unfortunately (or fortunately, depending

on your point of view), the factory 11"

Valeo clutch, that once was easily obtained through Ford Racing (M-7560-D46),

has been discontinued, so aftermarket replacements have become the norm. If you

really want to obtain a Valeo clutch as a replacement, their part number for the

'03/'04 Cobra kit

is (or was) 52802032.

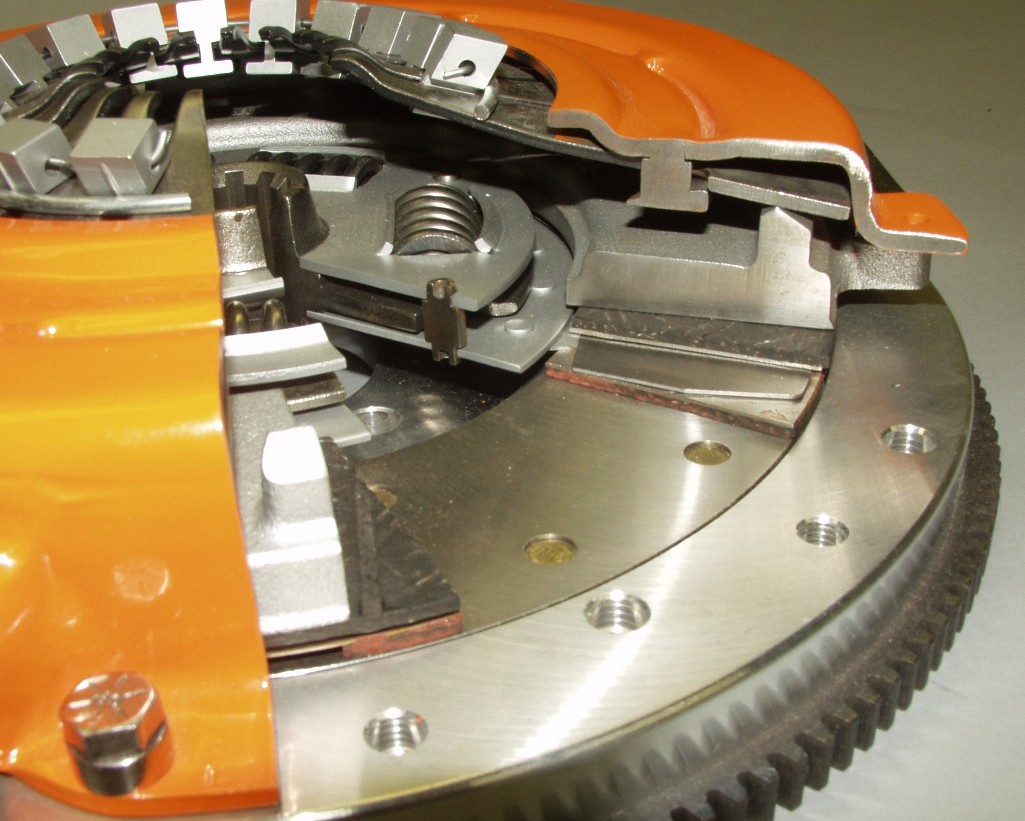

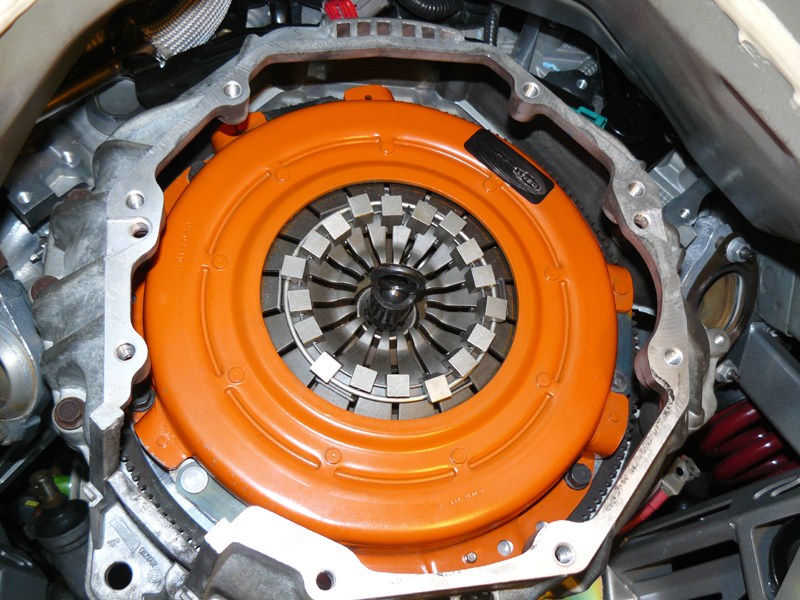

Actually, it is possible to buy the factory parts through Ford (in remanufactured form), but most enthusiasts change out their clutch with one of the many sets produced by a variety of manufacturers out there such as McLeod, Spec, Fidanza, and Centerforce. My choice here comes from Centerforce as you'd probably guess: the Dual-Friction (DF-800075). Coincidentally, Ford Racing lists the same package under their part number M-7560-T46, but that one is meant for 26-spline input shafts (I've stayed with the original input shaft and have had no problems at all).

Without making too much of a sales pitch, the thumbnail graphic from Centerforce does a great job of showing the finer points of their DF clutch line, along with the cutaway images above. It is common knowledge that as the RPM's rise, the pedal force with this clutch will decrease while the clamping force greatly increases - fine by me. Although the single-disc clutches are still "old-school" and dual-disc clutches have been gaining popularity over the years - especially as power levels have increased - I have no doubt this clutch is still a solid performer. I'll admit that some kits such as the McLeod RST and Centerforce DYAD are intriguing, but I'm still set on the DF for now.

As an update for 2016, my new Aluminator engine is done, and the DF clutch is in place and performing flawlessly. Installation was a breeze, and while I was at it, all the hardware was replaced, along with the addition of a "new" flywheel (see the note below). Keeping it simple, I also added some OEM parts, especially since they are readily available and inexpensive through Ford Racing. The pilot bearing, in roller form, is carried as M-7600-B, and the throwout bearing is M-7548-A. Also, there is a new bolt & dowel kit for the pressure plate: M-6397-A46 (the eight flywheel bolts were simply acquired through a Ford dealer). While I was back there, I also purchased a new "inspection plate", available through Ford Racing as M-7007-A, and had it powder coated to keep the rust away.

So far, the new clutch really is fantastic and the lighter pedal pressure is actually a bonus. It grabs quite well and has absolutely no chatter like so many others out there. As a slight twist, I went right out on my first drive behind the new engine and put this clutch through its paces immediately: no "granny driving" for 500 miles here (then again, no drag race launches either). Another great choice in parts for sure!

Note: Flywheel replacement is a popular option that frequently goes along with a new clutch. If you absolutely don't have to spend the money, the factory unit, formerly 2R3Z-6375-AA, can be "re-manufactured" by sending it to McLeod, where they will replace the friction insert for $125 (it is aluminum with a steel insert). If you happen to speak with a tech there, they will probably tell you they "don't recommend" resurfacing the flywheel, but I believe it will take a light cut just one time. It is, however, just as easy to have them handle the process so you can get one that is essentially new. They used to have a form right on their site for the return of your flywheel, but now there is a "Submit Return" button on the bottom of their Contact page for this.

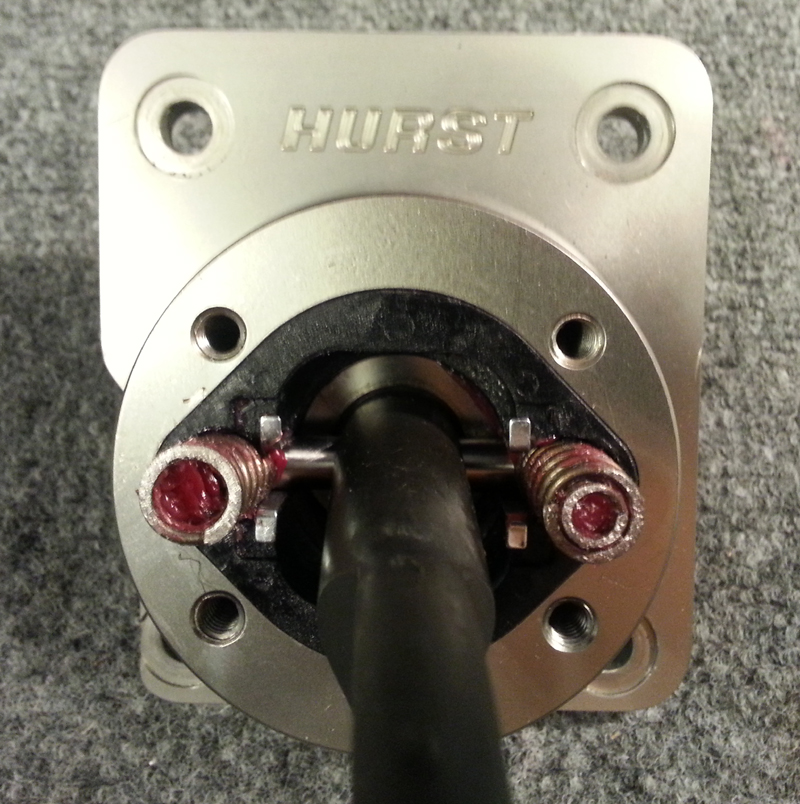

There are probably as many opinions out there as to which shifter is "best", as there are shifters themselves, and then some. While the factory shifter fits great in the "comfort" category, it leaves a lot to be desired when it comes to precise gear engagement. A "popular" shifter on the market doesn't work for me - I hate the short handle that actually required a longer reach for first, third, and fifth gears, so I had to be different. One of the main reasons for removing the stock shifter is to "tighten" the throw, which is done by raising the pivot point - which is something all aftermarket shifters will accomplish (well, most of them anyway). My favorite for short - and crisp - shifts was the same as it has been for almost the last 20+ years: Hurst. This time, it was the T-56 version they make for Ford Racing, the M-7210-T56.

Since this is such a common modification, I didn't bother documenting the installation process, but did get some pictures of the unit before and after the project was completed. For whatever reason, the FRPP version of the shifter comes bare anodized, as shown below, rather than with the gold finish that is the norm for their "Billet Plus" line and in the FRPP stock photo (kind of cool, even though you won't actually see it!). Hurst even supplies a rubber boot, that does a perfect job of sealing up the shifter while keeping any stuff out of the top. Very nice.

The version from Ford Racing actually comes with a long chrome handle, but I had no desire to use it since its extra length did not shorten the throw (and it looks awful anyway). The perfect solution was the stock handle bolted on with stainless steel bushings once made by UPR, shown above left. The ability to use the stock handle is actually one of several nice features of the Hurst, and with a throw of about 3", it is perfect. With the steel bushings in place of the factory rubber isolator, the handle is solid, and the shifts are incredibly crisp - without the ridiculous reach. Even better, I was able to make it completely stealthy by topping off the factory handle with a real 2000 Cobra R shift knob - once sold by FRPP as M-7213-F. The finished product is shown above and to the right, along with a peek at a Kenwood head unit I had experimented with briefly.

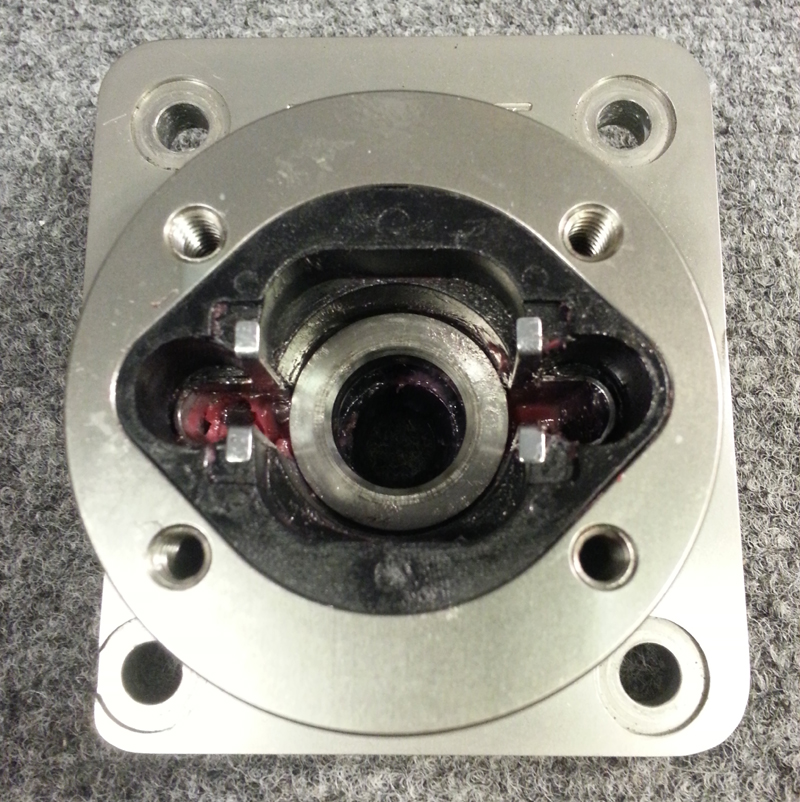

As for the other features I really like, there are two. The first is the composite center section, which is shown below left. With a billet aluminum base, there would be plenty of transmission noise transferred through the handle, but the composite insert completely isolates any of it. As an added bonus, the pivot of the shifter handle can be easily greased which helps keep the movement smooth and functioning like-new.

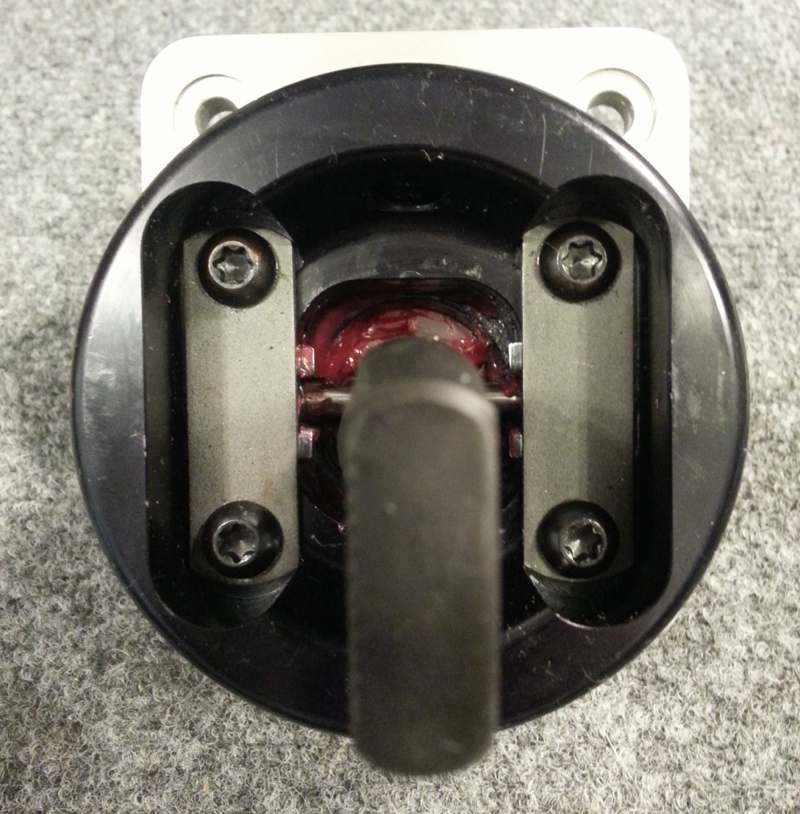

The other unique feature is the adjustable shift bias. This is accomplished by using springs on either side of the stick to force it down, which tightens the throw and contributes to the "self-centering" feature. Rather than using just two springs like other aftermarket shifters, you have the option of adding a third or fourth (a smaller spring insider the larger one). With four springs in place, the self-centering force is still there, just at a higher rate than with two. The use of three will then offset the bias to one side or the other, depending on where that spring is placed. I chose to add the third spring to the right of the stick which increases the bias in that direction (shown above, along with the trim ring and spring covers installed). This makes a shift from second-to-third, or fourth-to-fifth that much more positive rather than causing the stick to just "pop" back towards the neutral position. For any spirited driving, kiss those missed up-shifts goodbye!

Note: When it comes to replacing a shifter, there are many opinions as to the best way to seal it to the transmission. My personal preference is Permatex Ultra Copper silicone gasket maker. The stuff is indestructible and has never leaked in any application I have used it for, including several engine and transmission rebuilds over the years. While you are in the process of replacing a shifter, it's also the perfect way to fill the transmission with new fluid since you can pour it in right through the shifter opening rather than having to pump it up from below.

Early Terminator differentials were prone to leak thanks to the use of a generic silicone cover sealer combined with the movement allowed by the OEM rubber bushings when driven hard. To combat this, aftermarket bushings and an external brace are fairly common additions to stabilize the "pumpkin" in order to mitigate damage that can occur during wheel hop. Ford eventually began using their gray high-temperature sealant (Motorcraft TA-29) to stop the dribbles, but at the very least, stiffer bushings are a necessity to keep everything stable. As a step up from the brace, a fantastic option is a reinforced cover, such as the Ford Racing M-4033-G3 (also shown below), or the version produced by LPW Racing of Lancaster, PA.

I have had great luck with the Maximum Motorsports MMIRSB-45 bushing kit (made by Prothane), and for a brief period, a billet aluminum brace that was sold at one time by MotoBlue. The MotoBlue brace is now out of production, but other versions in steel are still available through Steeda or Billetflow. The brace itself bolts right over the stock cover to provide more support, and the bushings obviously replace the factory pieces, both front AND rear. Due to the differential upgrade covered in the next section, I made the step up to the Ford Racing cover, and it, along with the upgraded bushings have definitely not disappointed.

If you are planning an upgrade here, there are a couple points to consider. First, as already mentioned, replace them as a complete front and rear set. There is no sense in just putting new bushings in the front and leaving the factory bushing in the rear bracket (or vice versa), unless of course you are just still using OEM rubber all around. Second, the Prothane kit uses front bushings with a thicker lower half, so they raise the front of the differential slightly to adjust the pinion angle. The other polyurethane kit by Energy Suspension uses symmetrical bushings like the original rubber and won't give you that benefit. It's still not as precise as measuring and shimming, but it works nonetheless.

Despite what "poly-haters" will say, the MM/Prothane bushings are quite solid and hold the differential firmly in place. Those same haters have also been known to complain about alleged shortcomings, such as the bushings melting, while placing the blame on the material rather than focusing on the underlying mechanical issues. Adding to that, they'll claim this is an example of the "inferiority" of polyurethane while spouting off about how great another material like Delrin is instead. If you are running your car so hard that the differential is getting hot enough to melt the bushings (and most likely the seals as well), you are going to have problems with rubber, polyurethane, or yes, even Delrin. More details about bushing hardness is on my Suspension page and included in the chart below for reference.

| Bushing Material |

"Shore-D" Hardness (App.) |

| OEM Rubber |

20 |

| Energy Suspension polyurethane |

40 |

| Prothane/MM polyurethane |

60 |

| UHMW polyethylene |

70 |

| Delrin |

80 |

If an even harder material such as aluminum is your thing, especially with the shock of drag-strip launches, be aware the noise levels will go up. For a street-driven car, the polyurethane is ideal, but if you have to go solid, Maximum Motorsports has a perfect kit for this. Their aluminum mounts will definitely keep the differential from moving, and one nice feature of the kit is its concave spacers. These will allow the differential to pivot and accommodate for changes in the pinion angle while not placing any stress on the mounting tabs on the front of the case. For a complete run-down of it, download their installation instructions. Additionally, if you choose to add the Ford Racing differential cover, a custom milled version is available that will allow use of these heavy-duty mounts.

Whatever road you take, any increase in differential mounting stiffness will go a long way towards prolonging the life of your rear end. My choice of polyurethane combined with the upgraded cover has left me with no regrets at all, especially since the housing does not budge one bit. Even better: nice and quiet.

Note: Terminator owners did get lucky when it came to the differential pinion support: an improved version of this "brace", originally developed for the FR500 Mustang, went in to service for the 2003 model. It added two mounting ears that also sandwiched the forward bushings from beneath the differential, rather than just above like in the New Edge models, providing some additional stiffness (a comparison photo of them makes it easy). Fortunately, owners of earlier Cobra's - including the 2000R - could get these through Ford under the 2R3Z-5030-AA part number (apparently there are still some in the system). They used to also be available through Ford Racing as M-5030-F, but that is no longer the case. As alternative, there is a heavy-duty aftermarket version still made by Kenny Brown that is a good choice if you need one.

The factory traction-lok differential isn't all that bad, but it does have two shortcomings. First, the friction discs wear and eventually will cause the differential to slip. Fortunately, there is a Cobra-specific kit available through Ford Racing as M-4700-C when it is time for a re-build. The second is that when driven relatively hard, they simply get hot - thanks to the friction in those discs (it's not the fault of the bushings - get a clue!). Most drivers, however, are going to do just fine with the OEM differential, but I like to tinker and wanted to make an upgrade here to a stronger "torque multiplying" differential.

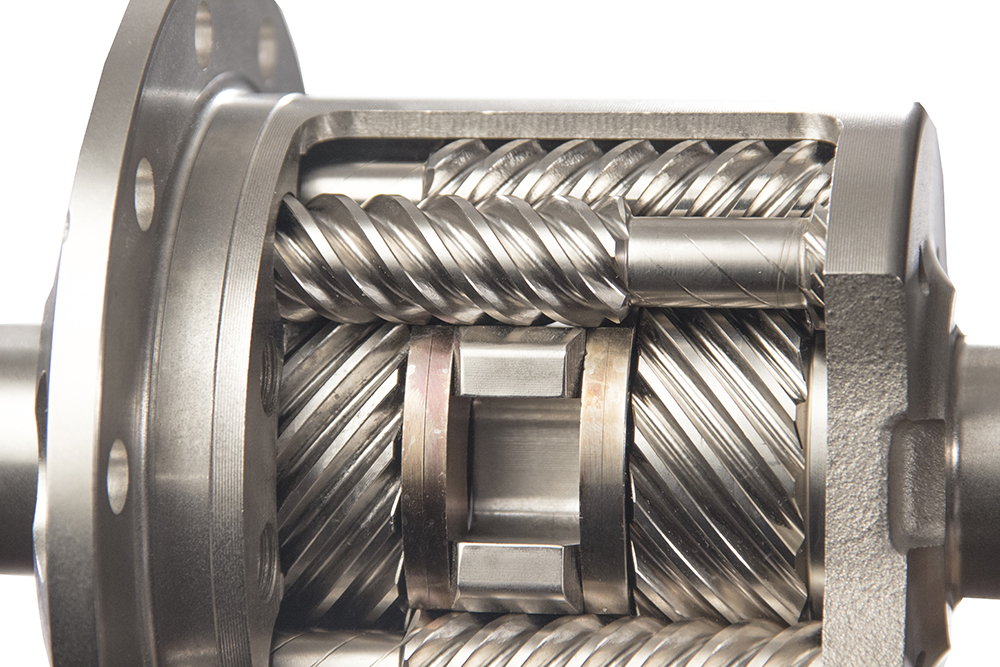

My choice here is a

Torsen (short for "Torque Sensing")

T-2R "Racemaster".

It is actually standard on the Mustang

FR-500S race car, and also sold through Ford

Racing as M-4204-T31H, or

originally as the Torsen

975420-0200L (which has been updated

to 975420-0200AF). These differentials

have the advantage of running cooler, with no friction discs to wear out, which

essentially makes them good for life. Adding to that, they do a much better job

of instantly distributing wheel torque, while also functioning as an "open"

differential during normal straight-line driving. For the basics, Torsen has a

nice summary

sheet, and I'll give the guys at Maximum Motorsports more credit for having a

Torsen page on their site that also has more information.

My choice here is a

Torsen (short for "Torque Sensing")

T-2R "Racemaster".

It is actually standard on the Mustang

FR-500S race car, and also sold through Ford

Racing as M-4204-T31H, or

originally as the Torsen

975420-0200L (which has been updated

to 975420-0200AF). These differentials

have the advantage of running cooler, with no friction discs to wear out, which

essentially makes them good for life. Adding to that, they do a much better job

of instantly distributing wheel torque, while also functioning as an "open"

differential during normal straight-line driving. For the basics, Torsen has a

nice summary

sheet, and I'll give the guys at Maximum Motorsports more credit for having a

Torsen page on their site that also has more information.

It is worth mentioning that there are two Torsen models available for the 8.8 rear: the T-2R & the T-2. They differ in the level they distribute torque, known as the "Torque Bias Ratio", or TBR. In simplest terms, the TBR tells you how much torque would be multiplied out to the axle that has more traction (i.e., the one that is spinning slower). The T-2R has a TBR of 4.0 which means it puts four times more power to the wheel that has the grip, compared to 2.5 for the T-2. A limited slip differential will also do essentially the same thing, but with the Torsen, you are getting an instant power transfer by way of the cooler running gears rather than the friction plates.

Along the lines of the TBR, there is one more point to consider. Since the Torsen differential is a torque multiplier, some resistance in the gearing is necessary to make this happen. If a wheel becomes airborne, it then loses any of that resistance and the TBR will essentially be zero for that wheel. This is actually the case for the T-2, but to combat the issue, Torsen developed the T-2R.

Note: Ford Racing states their T31H is not compatible with IRS housings for some reason. There is only one T-2R for the Ford 8.8" differential, which mates to both independent and solid rear ends (there is also a 28-spline version available under a different part number). This was also confirmed through conversations with the guys at both Torsen as well as MM, but I do not know why Ford Racing adds that stipulation since plenty of us use them with great results.

There is some information on the Torsen web site, but unfortunately, it is a bit lacking when it comes to the internals of the T-2R (well, other than the two pictures above). It consists, again, entirely of planetary gears, which are also illustrated clearly on the old T-2 data sheet. The thumbnail also shows an exploded view of another torque biasing differential, the Eaton Detroit True-Trac, which is similar to the T-2, but with a TBR of approximately 3.5. There is also a neat YouTube animation video of the True-Trac that is worth watching, along with a handful of others that can be found elsewhere on the web. Interestingly enough, Eaton markets the True-Trac as perfectly suited for drag racing, whereas Torsen and Ford Racing do not recommend it for the T-2 or T-2R. Since I have no interest in drag racing, that is not an issue.

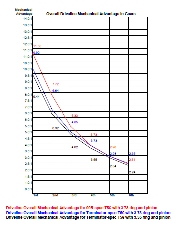

With

a new differential, complete with a Ford Racing rear cover (thus, the removal of

the brace), I couldn't resist making a change to the gearing, ditching the

factory 3.55 set. I had hoped at one time to get my hands on a '00R T-56, but

since that didn't happen, I decided a 3.73 ring and pinion

was a perfect match to the 2.66 first gear in the Terminators T-56. The

additional torque multiplication with the new gear ratio will suit the taller

first gear just fine, but for a graphic showing the mechanical advantage of a

few different gear combinations, click the thumbnail (courtesy of my buddy,

Tony). Also, don't forget that

with the new gear, you'll have to use a hand-held tuner to change the ratio or

your speedometer will be incorrect.

With

a new differential, complete with a Ford Racing rear cover (thus, the removal of

the brace), I couldn't resist making a change to the gearing, ditching the

factory 3.55 set. I had hoped at one time to get my hands on a '00R T-56, but

since that didn't happen, I decided a 3.73 ring and pinion

was a perfect match to the 2.66 first gear in the Terminators T-56. The

additional torque multiplication with the new gear ratio will suit the taller

first gear just fine, but for a graphic showing the mechanical advantage of a

few different gear combinations, click the thumbnail (courtesy of my buddy,

Tony). Also, don't forget that

with the new gear, you'll have to use a hand-held tuner to change the ratio or

your speedometer will be incorrect.

To make this project a bit easier, I decided to pick up a spare IRS housing and essentially build it from scratch rather than pull apart the factory differential (truth be told, I had a pro build it for me - this was one area I didn't want to skimp). Fortunately, a call to Tasca Ford made it easy to get my hands on all the additional parts through Ford Racing at a great price. For a complete list of what else I acquired, see the chart below.

|

Item |

Part Number |

| T-2R Differential | 975420-0200AF |

| Differential cover | M-4033-G3 |

| Gear set | M-4209-88373 |

|

Master installation kit |

M-4210-B2 |

| Pinion flange | M-4851-B |

| IRS bearing & seal set | M-4413-A |

| Gear oil (75W140) | Redline Lightweight ShockProof |

| Sealant | Motorcraft TA-29 |

Note: One last minor bonus of the Torsen diff is its weight. It is actually about five pounds heavier than the OEM limited-slip unit (25 vs. 20), which is fine by me. Normally, any weight added is a bad thing, but it doesn't hurt to shift some weight towards the rear, especially on a nose-heavy Terminator. If you are even more adventurous, an iron housing from a Thunderbird Turbo Coupe is also an option (just like Ford also did with the 2015 Mustang GT). Additionally, I dug the factory vibration damper back out to check it - almost another ten pounds there (if you are still able to use it). It's incredibly trivial, but every little bit helps when it comes to balance.